About us

Smater s.r.l. was born in 1981 as a company specialized in the production of injection molded plastic and rubber technical articles, which see their application in various industrial sectors.Quality, innovation, efficiency and reliability are the elements that have always distinguished us and allow us to relate excellently with major national and international players. We follow our customers step by step from design to delivery of the finished product..

SETTORI DI PRODUZIONE

Automotive

Trasmissione e distribuzione energia

Telecomunicazioni

Elettrodomestico

Valvole di sicurezza

Tessile

Metalmeccanico

Pompe ed accessori per la gestione dei fluidi

PRODUCTION SECTORS

Automotive

Energy transmission and distribution

Telecommunications

Household appliance

Security valves

Textile

Engineering

Pumps and accessories for fluids handling

ECOLOGICAL ENVIRONMENT

The company has decided to take action to protect the environment also in the field of separate waste collection andmanagement some waste, reduction of consumptionand reuse of water and materials.

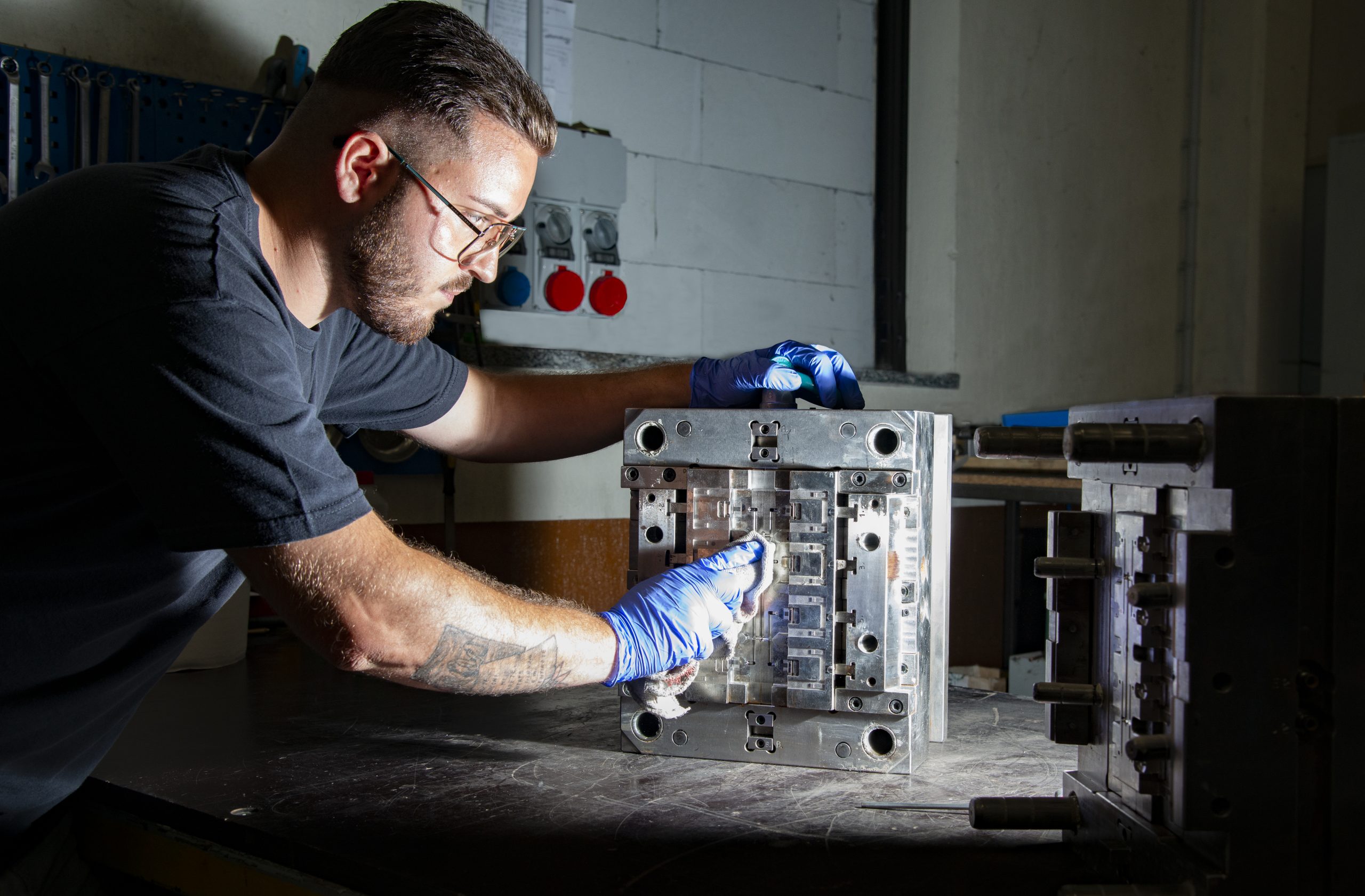

PLASTIC MOLDING

Starting from a drawing (2D o 3D) or from a sample (reverse engineering), we support the customer in finding technical solutions in order to optimize production times and costs and make their product performant.

Cosa Facciamo

RUBBER PRESSING

possible in terms of quality, timing and cost, the first fundamental step is the

mold design.

RUBBERMOLDING

After the analysis and collection of customer requests in order to arrive at the best possible solution in terms of quality, timing and cost, the first fundamental step is the design of the mould.

sqm – warehouse

for finished products

materials consumed

yearly

yearly

Quality Certificate

We are certified ISO 9001:2015 since 1998.

We respect the high quality standards expected by our customers, thus we are constantly improving our company and its organisational structure.

We can guarantee high quality products, at competitive costs and with the utmost attention to safety. All our products follow the standard quality plan that we designed and must pass specific tests in order to guarantee the highest quality to the end costumer.